Pump House

Since we finished the bore, the next order of business is to build a small pump house. Small enough to house the starter for the submersible pump that we will install once we get the electric connection. We wanted to be prepared with everything for the electric connection. Again we had to go through a lot of thought and planning. Should we build something really small like a 5 feet by 5 feet room, just enough to house the starter for the pump and some tools. Or should we build something bigger for future needs. After much discussions and thought, we decided to go with a slightly big room with bathroom so we can use it when we visit the farm instead of worrying about where to relieve ourselves.

After discussing our plan for a bigger house with bathroom with Mr. J, he suggested that we build a house that is slightly bigger than 20 feet on one side. He said that if we buy any pipes for drip irrigation or sprinklers, the size of the pipes will be 20 feet and if we have a room that is slightly longer than that, we can fit the pipes inside the house and not worry about theft, or cattle trampling on the pipes and breaking them etc. We thought that this was a good idea. We could also store any farming tools inside the house too. A bathroom could come on one side and have enough place to setup the pump starter. For those of you who don’t know, a pump starter board looks like the below picture.

Now comes the problem of budget. Mrs. re-ynd is running out of funds. The only income she has is a small rental income which she was diligently saving up for anything farm related. As you know, I have not planned on buying a farm after retirement and hence I have nothing saved up for it. I could not help her financially. We decided on a budget of Rs. 2.5 lakhs for a 20 feet x 10 feet pump house with a bathroom.

I started to work on the design of the pump house. For those of you who don’t know, the house we are currently living in Bangalore is designed by me. We initially hired an architect but I did not like his designs. And explaining things over phone and email was getting to be tedious. The few times I visited his office, we could not agree on a design that I liked. I kept asking him to make a lot of modifications which required time. So he would come back with updated design in a few days and again I give feedback and it took more days. I decided this is not going to work and thought I should teach myself some architecture software so I can build the 3D design of my house, which is exactly what I did.

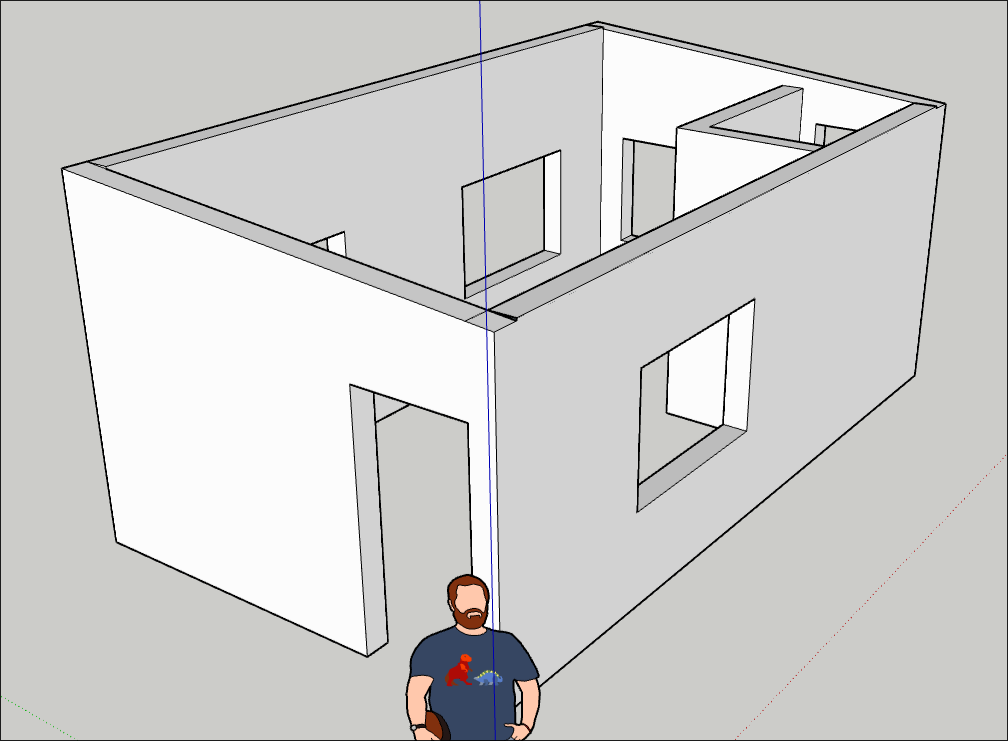

I taught myself Sketchup using youtube videos way back in 2011. Built the full 3D model using the software and worked with the construction workers directly. Since I had the 3D model, I would show them how the house should look like in my laptop. I could give them measurements to the exact feet and inches so they can plan how to lay bricks etc. Of course I did work with a structural engineer to get the pillars and beams in the right location with the right sizes. I was only doing the architecture part, not the strength of materials part :). So don’t worry, the house is structurally sound in spite of using my designs. I think the constructors did a good job of translating my design to reality. You be the judge.

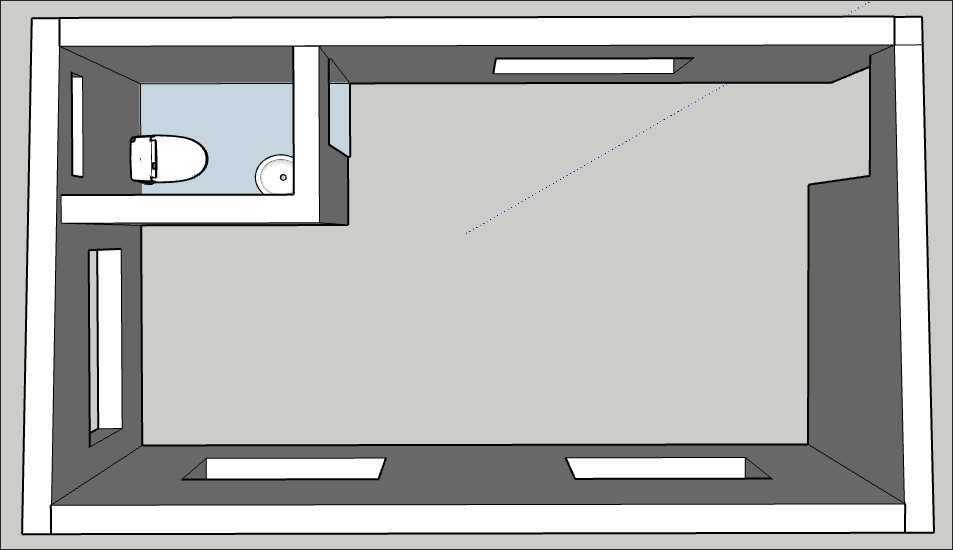

Anyway, I decided to use Sketchup again to design the pump house. The concept is really simple as opposed to our current house. We just need a rectangular shape of approximately 20 feet by 10 feet. Throw in a bathroom in one corner and be done with it. Need an entrance and a whole bunch of windows for ventilation. So here is the initial design that I came up with.

Our idea was to have a sloping roof with metal sheet or something cheap on the top.

So we started talking to various contractors to get a quote for how much it would cost to build according to our design. Around the same time, we were wondering if we should go with a more sustainable building materials instead of using fly ash bricks and cement. We were worried if the sustainable material would increase the cost. Eventually we decided to go with more earth friendly material for a higher cost. Details in my next post.

By the way, I forgot to mention. Before deciding on building a pump house, we actually wondered if we could have a shipping container modified to use as a pump house. We know a farmer who had done precisely that. Got a discarded shipping container delivered to their land and modified it to a narrow and long house with living room, bedroom and bathroom. They had to get some welders and cutters to make windows and doors and that is it. We really liked the idea but did not pursue for a few reasons.

Finding and transporting such a container would be prohibitively complicated and expensive. Then we were worried about the heat inside the house, because, it is a chunk of metal on all sides. Someone suggested padding the walls with insulating foam to reduce heat, but at this point, the cost will go through the roof. I was also worried about the durability because it will rust easily. So we have to take good care of painting red oxide layers frequently and make sure water does not stand on the surface.

We even wondered if we could buy a prefabricated house and get it shipped to the farm. The cost is still going to be higher than local construction. Even a house built out of prefabricated walls and roof was not going to be cheap especially in that remote village. If I was constructing it here in Bangalore it could have been a viable option.